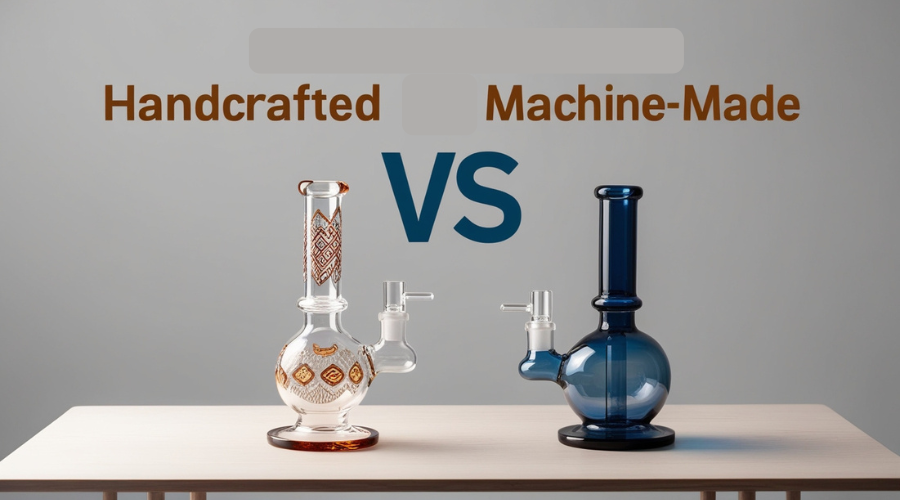

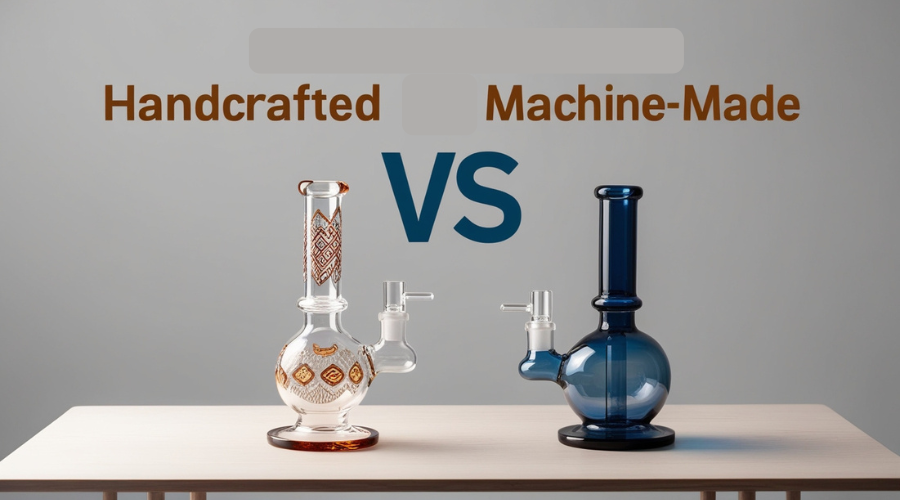

Handcrafted vs Machine-Made Glass Bongs: What B2B Buyers Should Know

If you’re new to procurement for smoking accessories, it’s easy to lose time by comparing “handcrafted” and “machine-made” bongs and getting confused between the two. as if they’re just marketing labels. In B2B, both these variants behave differently in every aspect from quoting, sampling, quality control, to lead time reliability, packaging performance, and claims handling. This guide helps you choose the right direction for your assortment and reduce avoidable problems like mismatched specs, inconsistent reorders, transit breakage, and slow dispute resolution.

You’re likely sourcing Spaceman-themed (or “Spaceman” labeled) glass bongs and seeing two kinds of offers that don’t line up cleanly. One supplier quotes a premium handcrafted line with flexible options but vague tolerances. Another offers a machine-made line with cleaner specs but fewer unique or eye-catching design details. If you try to decide based on photos alone, then that is guesswork. The real differences show up in restocks, breakage rates, and how easily you can keep listings accurate.

At-a-Glance Comparison

|

|

Handcrafted Glass Bongs

|

Machine-made Glass Bongs

|

|

Unit cost

|

Higher, more variation by design |

Lower, typically more stable |

|

Consistency

|

Moderate; variation is normal |

High; repeatability is the goal |

|

Perceived value

|

Strong for premium positioning |

Strong for standardized value |

|

MOQ

|

Often flexible, supplier-dependent |

Often scalable, line-dependent |

|

Lead time

|

Less predictable |

More predictable |

|

Defect profile

|

Piece-to-piece variability |

Batch-level risk if process drifts |

|

Best fit

|

Boutique, premium, limited drops |

High-volume replenishment |

Glass Quality Specs to be aware of during sourcing

As you start your procurement process, you will commonly see terms like borosilicate, thickness, annealing, and joint quality while browsing for suppliers. You don’t need to be overly technical, but you should treat these terms as risk indicators. Borosilicate is widely used for better temperature-change tolerance. Thickness is a signal of quality but consistency of thickness in stress areas matters more in usage than just general thickness. Annealing is controlled cooling, and weak annealing increases cracking risk later. Then there is joint quality. Joints are frequent break points in transit and daily handling.

Handcrafted Spaceman glass bongs (B2B considerations)

Where handcrafted performs well

Handcrafted Spaceman-style bongs often support premium positioning because the design can feel more distinctive and the product can be presented as “limited edition” even when you’re buying wholesale quantities. If your assortment strategy relies on catering to premium audience or gifting, handcrafted items can improve margin per unit and reduce direct comparability with commodity listings.

Handcrafted bongs can also be useful when you want a smaller inventory to test market appeal and demand without committing to a very high volume order.

The operational trade-offs you must plan for

If you promise exact dimensions in listings or require exact uniformity for planograms, handcrafted can create work and returns. Lead times are also less reliable in handcrafted versions. New buyers often accept a quoted lead time without confirming whether it includes production, cooling/annealing time, QC, packaging, and export handling.

What to request to prevent defects

Before ordering, get written tolerance ranges for dimensions and weight, plus clarification on what kind of visual faults are considered acceptable. Ask for photos of multiple units from the same order. A single sample will not tell you the entire story about the quality you are receiving. Confirm packaging structure and protection method in writing, because packaging is vital for product protection during transit and lack of quality packaging means that the whole order can become damaged. Also, clarify the grading criteria of bongs during the bulk purchase. if the supplier sorts output into different quality tiers, you should specify which tier you are buying.

Machine-made Spaceman glass bongs

Where machine-made performs well

Machine-made lines are usually easier to scale and repeat. If you need stable SKUs, predictable restocks, and consistent product photos, then Consistency also helps you standardize basic quality control at receiving, because machine-manufactured bongs do not have much artistic variation.

What to request to prevent defects

The most important machine-made risk is batch-level defects. This only occurs If the process setting was wrong before production of a batch. The same fault appears across a whole batch. That can produce a larger operational problem than a one-off handcrafted variation. To safeguard against this, disciplined sampling and clear acceptance criteria, followed by a pre-shipment check for larger orders, are a solid approach.

What to request to protect reorders

Ask for batch identification on cartons and stable SKU mapping across reorders. Do not forget to confirm packing specifications like packing quantities, labeling etc because these affect freight quoting and warehouse handling. Also, ask how QC is performed and how failures are handled.

Quality & durability comparison

Focus on what actually creates cost

Your highest hidden costs are breakage, claims handling, and the time spent documenting issues. In glass, a slightly higher price with better packaging and tighter quality control often reduces total landed cost.

Common failure points for Both Types

Joints are a frequent weak point in both kinds of bongs. Misalignment, weak joins, or stress marks can increase breakage risk during shipping and handling.

Devising quality criteria that works

Define, in writing, what counts as a functional failure, so that the line between a minor surface fault and a structural fault is clear. Your expectations should be communicated clearly and for this product, these are: leak-free design, precise joint alignment, and quality packaging. For volume orders, define an acceptable defect rate and a remedy if the shipment exceeds it. The criteria should be simple enough for the supplier to follow and easy for your procurement team to verify.

Pricing, margins & total landed cost (B2B reality check)

Why cheap quotes are expensive in the long run

Substandard suppliers cheat buyers by quoting only unit price. The issue with this quote is that it does not include many other costs that can impact the final cost.Total landed cost is more inclusive than unit price and accounts for product price, freight, duties/taxes where applicable, packaging extras, receiving labor, and the expected cost of defects and damage.

Profit margin behavior by type

Handcrafted often supports higher shelf prices and a stronger margin per unit. This is because it appeals to the premium buyer segment. However, handcrafted bongs have downsides as they require more careful merchandising and tighter expectations for quality. Machine-made often supports higher unit velocity and easier sourcing. But margins may be more sensitive to competitive pricing. Choose based on which profit profile matches your marketing and channel strategy.

A usable landed-cost model

A practical way to think about it is:

Landed Cost per Sellable Unit=Product Cost+Freight+Duties+Packaging Extras+Expected Defect/Damage CostExpected Sellable UnitsLanded Cost per Sellable Unit=Expected Sellable UnitsProduct Cost+Freight+Duties+Packaging Extras+Expected Defect/Damage Cost

MOQ, lead times & supply chain reliability

Interpreting MOQ without getting trapped

MOQ signals how the supplier runs production. Lower MOQ can help you test, but it may come with a higher unit cost that cuts into your margins. Higher MOQ can improve pricing and consistency, but increases inventory risk. The best strategy is to match the MOQ to your test plan and reorder frequency.

Lead time: define it the same way every time

Lead time should be defined from deposit date to ready-to-ship date, with transit and clearance handled separately. Many delays that happen are avoidable because buyers assume lead time includes everything. Ask for a written schedule covering production, QC, packaging, and dispatch to make sure the quoted lead time is genuine.

Reliability questions that are Crucial in Bulk Procurement

If you plan to reorder, confirm if the supplier can reproduce the same SKU with the same specs and packaging. Another worthy question to ask is how they maintain tooling consistency for machine-made products. For handcrafted ones, inquire about quality benchmarks for ensuring maker consistency.

Conclusion

The practical difference between handcrafted and machine-made Spaceman glass bongs is how predictable your outcomes will be. Machine-made typically supports consistency, replenishment, and lower operational overhead. In contrast, handcrafted typically supports differentiation and premium positioning, but requires tighter tolerance definitions, stronger sampling discipline, and more careful lead time planning.